This overview is intended to explain the key features of LPKF's depaneling machines especially the differences between the various systems in the portfolio. In addition, you will learn more about our software solution as well as optional expansion options such as software packages and service packages.

| Max. Working Area | 350 mm x 350 mm | 500 mm x 350 mm | 533 mm x 610 mm |

| Positioning accuracy | +/- 25 µm | +/- 20 µm | +/- 20 µm |

| CleanCut Technology | limited* | unlimited | limited* |

| Software | Circuit Pro | ||

| Service Packages | Basic / Classic / Premium Service Package | ||

| Automated Handling | Scalable automation solutions | --- | |

*It depends on the selected laser power

LPKF's depaneling systems are suitable for a wide range of applications (e.g. FR4, FPCBs, ceramics or SIPs) due to their flexibility and various integrable laser sources. When choosing the right depaneling system for your requirements, we will be pleased to guide you.

LPKF CuttingMaster 2000

The CuttingMaster 2000 is characterized by its compact design, simple operation and unique price-performance ratio, making it one of the most economical depaneling systems.

The depaneling systems are available in several variants, which operate with a pulse duration in the nanosecond range, but differ from each other with regard to the laser source and thus in particular with regard to their laser power as well as wavelength.

| Manual | Automated | |

|---|---|---|

| Max. Working Area | 350 mm x 350 mm | 350 mm x 250 mm |

| Positioning accuracy | +/- 25 µm | |

| System dimensions | 875 mm x 1510 mm (2070 mm)* x 1125 mm | |

*Height including status light

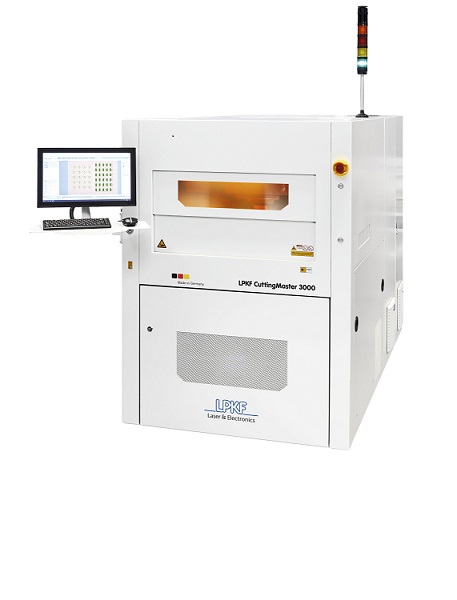

LPKF CuttingMaster 3000

Characterized by its high efficiency, performance and quality of cut edges, the CuttingMaster 3000 is a depaneling machine that delivers the best results for almost any cutting task.

The CuttingMaster 3000 has several variants that operate with pulse durations in the nanosecond and even picosecond range. The laser power can reach up to 65 watts. Using the LPKF Clean-Cut technology, the CuttingMaster 3000 can achieve technically clean cutting edges that set new standards.

In contrast to the CuttingMaster 2000, this system offers an even slightly larger working range and further increased accuracy.

| Manual | Automated | |

|---|---|---|

| Max. Working Area | 500 mm x 350 mm | 460 mm x 305 mm |

| Positioning accuracy | +/- 20 µm | |

| System dimensions | 1050 mm x 1530 mm (2120 mm)* x 2000 mm | |

*Height including status light

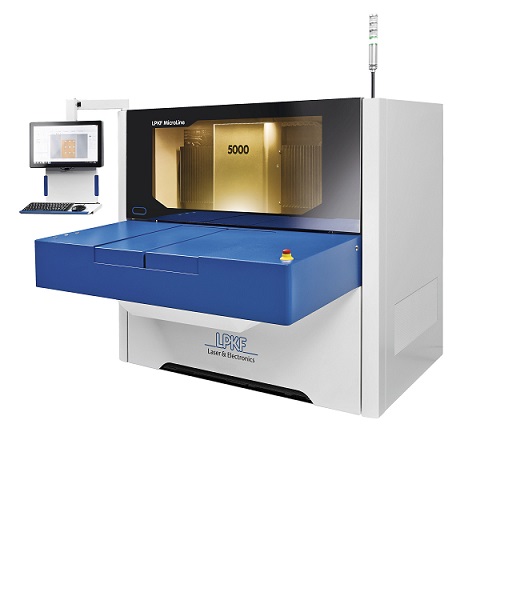

LPKF MicroLine 5000

In addition to drilling, the MicroLine and PicoLine 5000 can also be used to cut industry-standard plate sizes. The multi-purpose systems are equipped with high-power UV lasers that can also be used for cutting complex contours at high speeds with a very small cutting channel.

The 5000 series depaneling and drilling systems have several variants with UV laser sources offering pulse durations in the nanosecond and picosecond range as well as different laser powers.

| MicroLine 5000 | |

|---|---|

| Max. working area | 533 mm x 610 mm (21" x 24") |

| Positioning accuracy | +/- 20 µm |

| System dimensions | 1660 mm x 1720 mm x 1900 mm (66" x 68" x 75")* |

* Height incl. status light = 2200 mm (87")

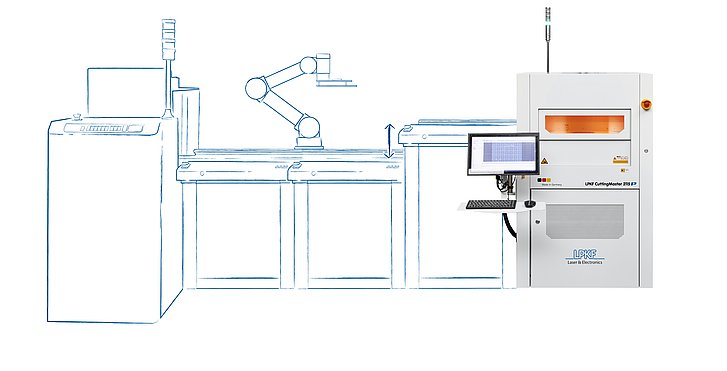

Automated Handling

To meet the requirements of Industry 4.0 and increasingly self-sufficient production processes, LPKF offers customized automation solutions for the company's own depanelling systems. These solutions are adapted to the individual needs of the customer. The range of solutions includes the expansion with individual modules up all the way to a completely autonomous stand-alone solution for your depaneling system.

The automation solutions provide customers with more control and transparency over their own production process and the associated data flow, enabling them to further increase the effectiveness of their production.

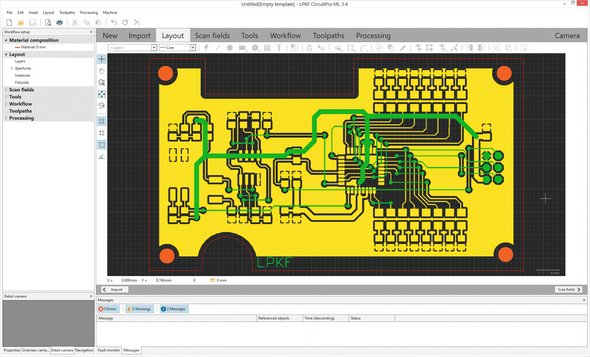

Software

With every depaneling machine, a full version of LPKF's own powerful CircuitPro software is supplied at no extra charge. It can be expanded with additional optional software solutions depending on customer requirements and needs:

- Barcode Recognition

- Barcode & Serial Number Engraving

- Traceability & Supervisor Statistics

- Bad Board Detection & Handling

- Connection to MES System

Service Packages

LPKF supports their customers worldwide at the highest level of quality. Our range of services extends from installation, calibration, and maintenance of the depaneling system to operator training, process optimization, and complete service packages.

Our service packages are available in three levels to meet different customer requirements:

- Basic Service

- Classic Service

- Premium Service