Enhancing your production´s efficiency

High-end laser plastic welding with the expert

When it comes to joining plastic components, laser technology has gained an excellent reputation. It efficiently creates plastic joints of unrivaled quality and cost-effectiveness. LPKF has many years of experience and is a global leader in this area.

8 + 8 = convincing arguments for LPKF laser plastic welding

8 advantages of laser plastic welding with LPKF

- Simple process setup - (nearly) child's play

- Efficient processing in seconds

- Highly flexible processing thanks to easy job setup

- Reliability through process monitoring

- Top quality standards

- Best possible welding results

- Highly available, low-maintenance machines

- On request: Sample

8 benefits of the technology

- New and one-of-a-kind: Identical and repeatable results on all calibrated LPKF laser welding machines

- Perfectly clean: no released particles, no solvents no chemical treatment, no surface damage

- No mechanical stress in the component; joints are even possible close to electronic

- As solid as the material itself: joints that hold

- Precise results: exact weld seams inside components

- Truly impermeable: up to protection class 67

- Aesthetically appealing results

- Flexible and with online process monitoring

For you - from us: Learn more about laser plastic welding

Application experience: Laser plastic welding

We are the experts for safe, reliable, and economical plastic welding

Nowadays, plastics can be found everywhere: on supermarket shelves, in cars, in medical technology, in the toy industry, in the furniture industry, etc. In all of these areas, plastic components are joined together. If this process needs to be particularly high-qualit, reliable, and stress-free then laser plastic welding is the universal procedure of choice.

This is where LPKF comes in. Particularly in our three core industries – automotive, medical technology, and consumer electronics – we know this field like the back of our hand. We take advantage of our knowledge of the standards, regulations, requirements, and challenges in the various industries by putting our extensive expertise in laser plastic welding to targeted use.

Countless products have already been produced using our machines – from small electronic housings to large fittings – and the number keeps growing every day. LPKF welding machines are at home in many branches of industry. See for yourself.

Your Idea

Getting started is easy

Each project is special. We know that. And that is why we are glad to take on your assignments. Upon request, we will recommend materials or designs for developing products that are as efficient as possible and that are economically and technically superior to conventional materials and designs. We will find just the right machine for you and will calculate the optimum process parameters for you.

We will be at your side from the concept stage to the final product. If you already know us, then you are aware of this by now.

And if not... take advantage of the chance to have simple processes and top results – and get in touch with us!

Our expertise for your success

Talking with you is important to us.

Even if you have been joining plastic components with other technologies so far... you will obtain reliable, fast, and high-quality results using laser technology. Please allow our experts to advise you.

We are well-versed in this field and will accompany you through all development stages on the way to your solution.

We will accompany you - from the inital idea to the finished product.

Just the right solution for every application

The LPKF product portfolio includes laser systems for reliably welding very small to large parts, with weld seams from 100 μm to several millimeters in size.

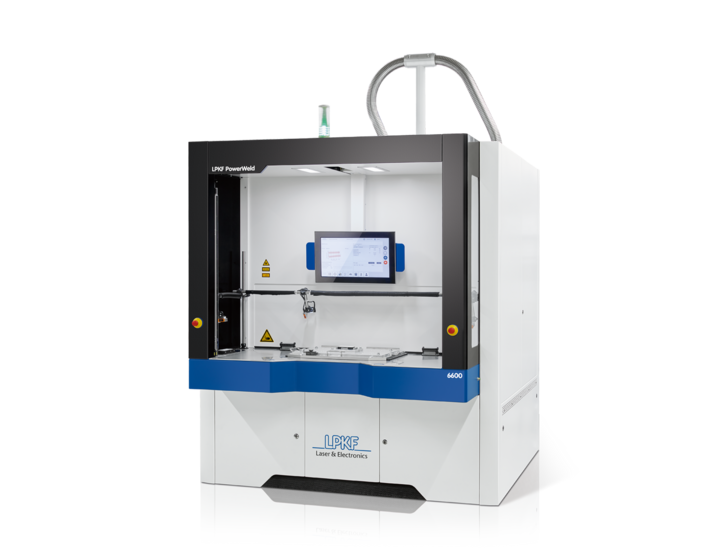

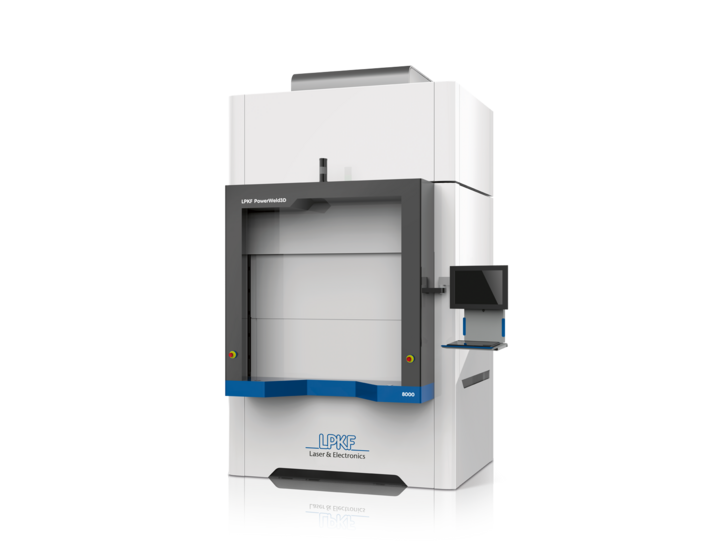

- Stand-alone systems of the PowerWeld family are especially compact and are suitable in a wide variety of production environments.

- Integration systems of the InlineWeld family can be directly incorporated into each and every production line – with either a manual or automated component feed system.

- If unique solutions are necessary, such as special feed systems, then our customer-specific solutions will come into play. We will gladly design a custom-made system for you.

Click through the four tabs for more information:

![[Translate to USA:] Next Generation Laser Plastic Welding](/fileadmin/mediafiles/_processed_/8/a/csm_Header_WQ_01_6b26a6178f.jpg)

![[Translate to USA:] LPKF PrecisionWeld in action](/fileadmin/mediafiles/_processed_/8/7/csm_LPKF_1302_PrecisionWeld_TF_003_4f98f0399a.jpg)

![[Translate to USA:] Precise welding seams - not only for perfect pool lighting](/fileadmin/mediafiles/_processed_/c/e/csm_WQ__Application_WQ__035_90d3c90e43.jpg)

![[Translate to USA:] Reliability through optimal interfaces](/fileadmin/mediafiles/_processed_/4/6/csm_WeldPro2017_2_1db6cd31f6.jpg)

![[Translate to USA:] This unit is equipped with a lot of expertise](/fileadmin/mediafiles/_processed_/8/7/csm_LPKF_PI_1706_PU-W_6c4b061bb9.jpg)

![[Translate to USA:] Many years of application experience](/fileadmin/mediafiles/_processed_/9/5/csm__01_4612_edited_05901ae029.jpg)

![[Translate to USA:] Welding processes from LPKF](/fileadmin/mediafiles/_processed_/e/a/csm__01_4248_df6fdcba21.jpg)

![[Translate to USA:] Core industry: Automotive](/fileadmin/mediafiles/_processed_/f/7/csm_Fahrzeug_Highlights_160822_cmyk_c1d9671137.jpg)

![[Translate to USA:] Core industry: Medical technology](/fileadmin/mediafiles/_processed_/8/b/csm_Insulin_Management_08b6c0af99.jpg)

![[Translate to USA:] Core industry: Consumer Products](/fileadmin/mediafiles/_processed_/e/9/csm_WQ__Application_WQ__003_c6d6d2d89f.jpg)

![[Translate to USA:] Expertise in plastic joints](/fileadmin/mediafiles/_processed_/e/3/csm__01_4341_87d63d469b.jpg)

![[Translate to USA:] Laser plastic welding - consultation from our experts](/fileadmin/mediafiles/_processed_/4/b/csm_F18A4538_735b834df0.jpg)

![[Translate to USA:] Laser Plastic Welding - Expertise in Laser Technology and Industry Applications](/fileadmin/mediafiles/_processed_/b/5/csm__01_4395_b9a9399380.jpg)

![[Translate to USA:] Design phase](/fileadmin/mediafiles/user_upload/industries-and-technologies/laser-plastic-welding/01_EN.jpg)

![[Translate to USA:] Pilot phase](/fileadmin/mediafiles/user_upload/industries-and-technologies/laser-plastic-welding/02_EN.jpg)

![[Translate to USA:] Ramp-up phase](/fileadmin/mediafiles/user_upload/industries-and-technologies/laser-plastic-welding/03_EN.jpg)

![[Translate to USA:] Series production](/fileadmin/mediafiles/user_upload/industries-and-technologies/laser-plastic-welding/04_EN.jpg)