Benefits

Flexibility & Autonomy

Laser systems for in-house use increase the flexibility to test different materials or layouts within a very short time. It gives you full control on your project and the freedom to prove your concept immediately. Start the next iteration of your project, independent from any service provider or internal order process. Basic research on innovative materials or improvement of existing applications. Both are perfectly supported with in-house laser tools.

Safe & Fully Chemical-free

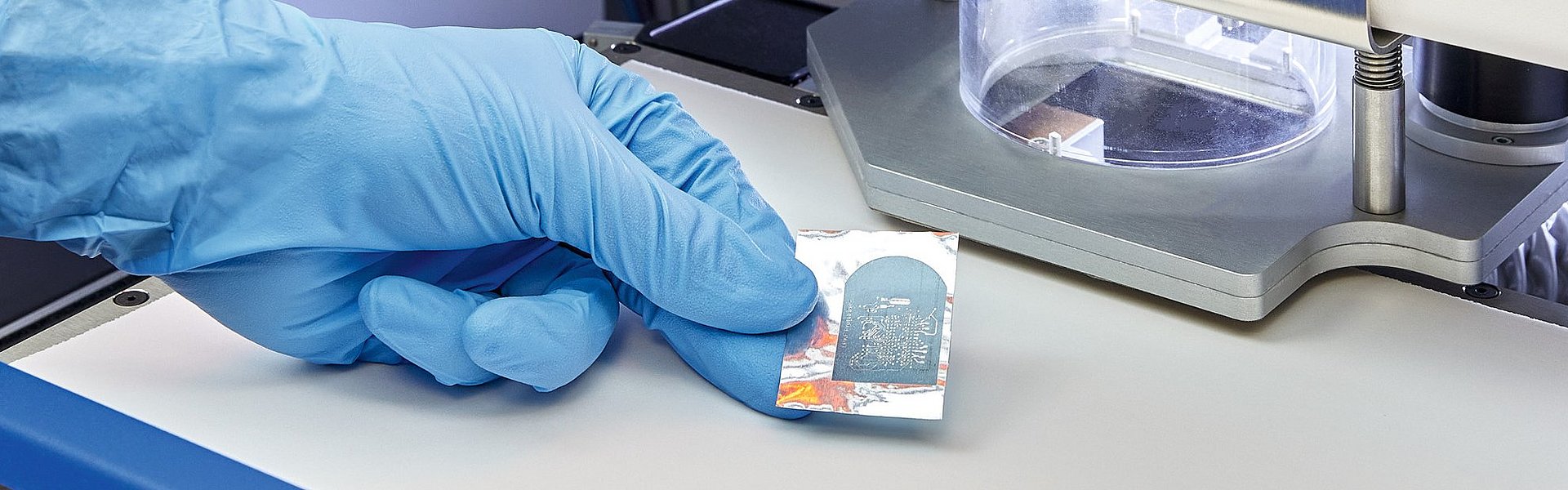

The laser systems are ready on demand, no setup time required, and no chemicals are needed for the process. Biocompatible materials or a flex-electronic sensor intended to come into contact with human skin will not be exposed to any chemical contaminants.

Reproducible & Scalable

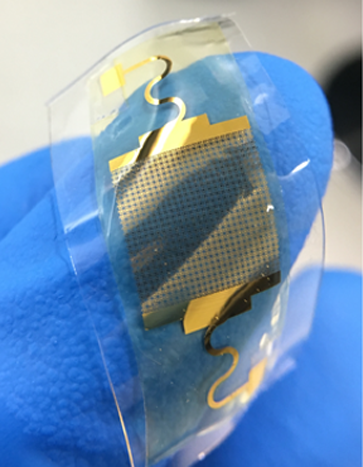

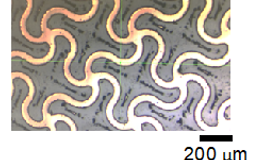

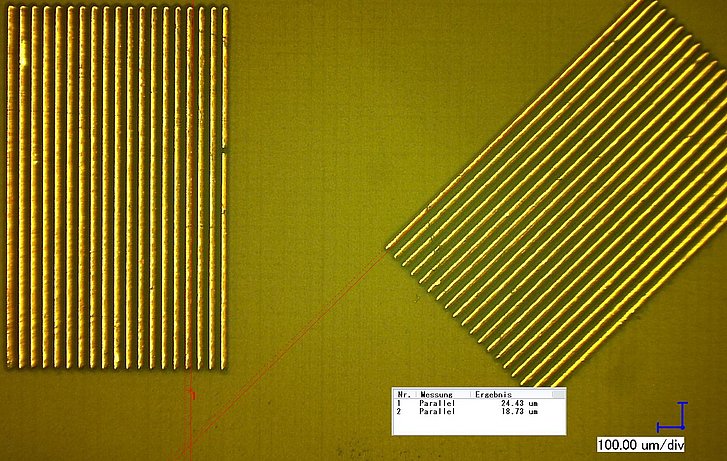

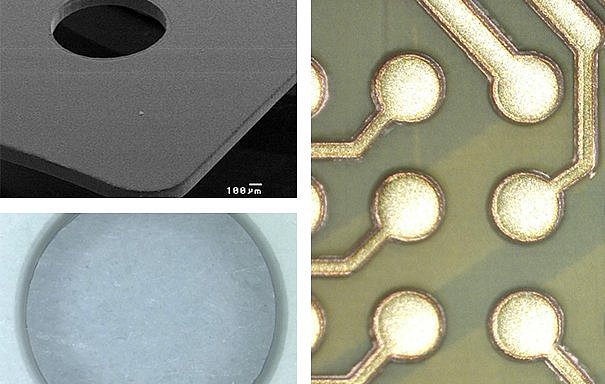

The use of ultrashort pulse lasers ensures reproducible, high quality surface features. The smooth sidewalls, sharp edges and tight radii achieved by laser etching is unmatched in terms of quality. Channels and cutouts in solid or brittle materials are easy to process without damage or visible cracks. With the ability to also perform small production runs with reliable high-quality, you will have the assurance that new applications have been through several cycles of building, testing and improvement to guarantee that your product not only gets to market more quickly, but also ensures robust performance of your product once in the field.

The laser systems

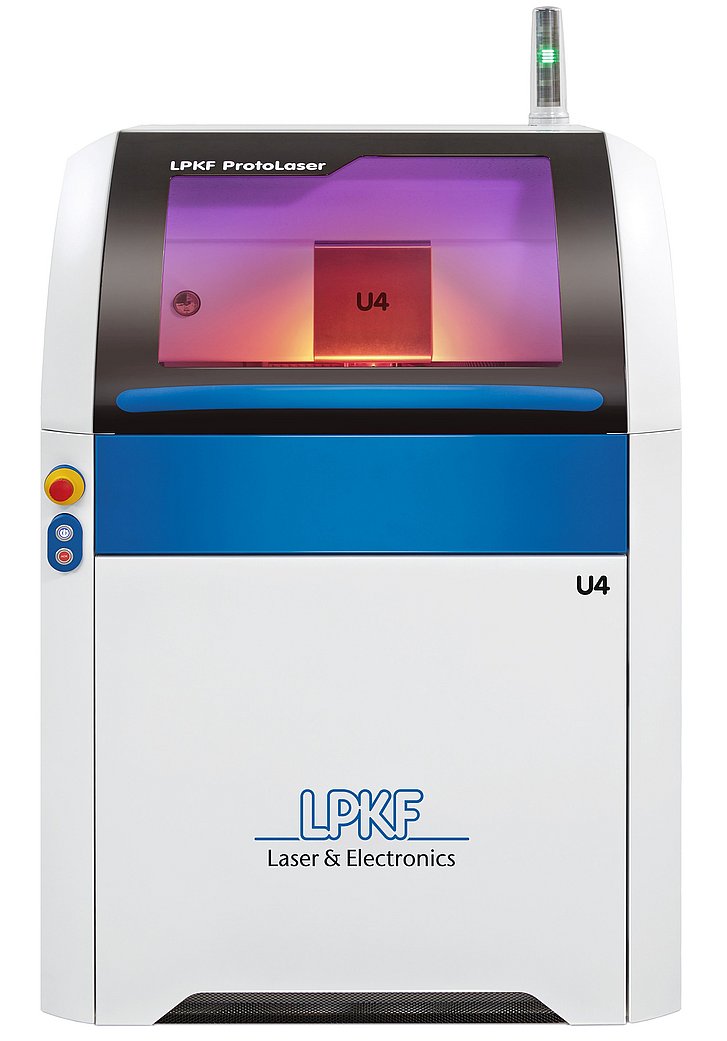

The LPKF ProtoLaser U4 processes many materials with an integrated UV laser.

At the same time, the system is easy to install and even easier to operate. The high pulse energy of the UV laser leads to an ablation process without residuals: Geometrically exact contours are the result. The LPKF ProtoLaser U4 can structure or cut a wide variety of materials quickly and cleanly. An extensive material library already provides the laser parameters for the most important materials. Tooling costs are a thing of the past, the ProtoLaser U4 works without any contact to the material. Micro material processing benefits from the small diameter of the laser beam, the highly precise focusing in the Z-axis and the exact control of the processing positions.

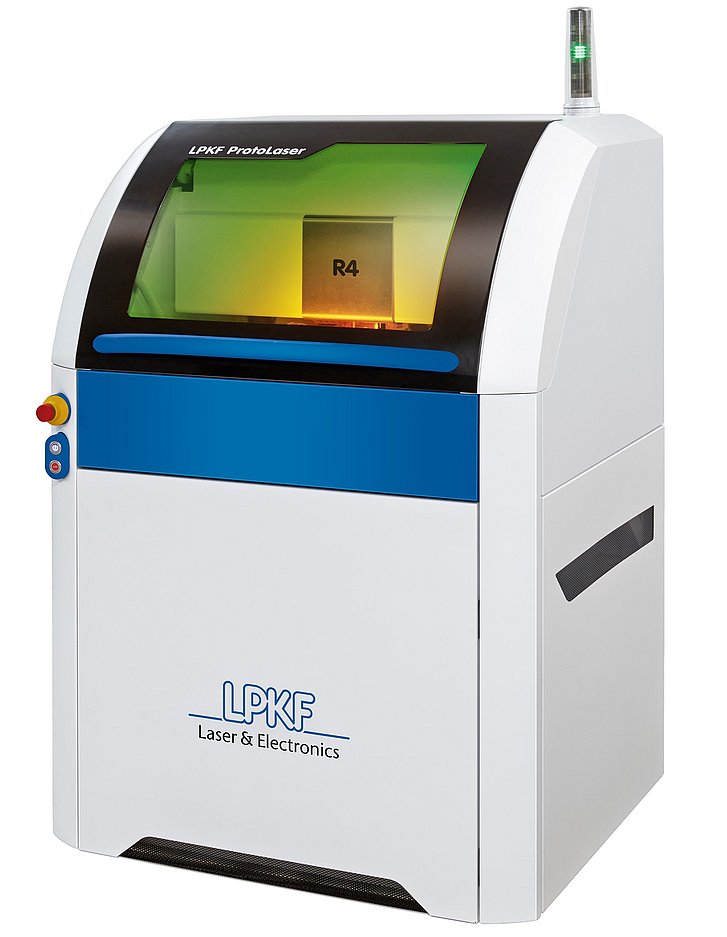

The LPKF ProtoLaser R4 operates with short picosecond laser pulses.

This allows highly precise structuring of sensitive substrates as well as cutting of hardened or fired substrates. Due to the short pulses, there is practically no heat transfer, the material hit vaporizes directly. This thermal effect is important for cutting as well as for surface processing of temperature-sensitive materials. Due to the low heat input, no micro-cracks occur in the material. The high-precision hardware as well as the integrated camera are supported by the easy-to-use LPKF CircuitPro software. This enables the user to implement projects on challenging materials in their own laboratory within a very short time.

Related publications and references

LPKF ProtoLaser systems have been successfully used over many years in electronic research projects all over the world. Now more and more applications within the medical industry use LPKF´s laser technology to speed-up research projects. Basic research on new innovative materials, evolving existing products into smaller dimensions with additional functionality, or simply saving time and money during development, are all primary drivers for having a ProtoLaser system in your own lab.

Read more below about our state-of-the-art research equipment, and learn about just a few of the applications brought to reality by LPKF ProtoLasers.

- Krishnan, S.R., Arafa, H.M., Kwon, K. et al. Continuous, noninvasive wireless monitoring of flow of cerebrospinal fluid through shunts in patients with hydrocephalus.

npj Digit. Med. 3, 29 (2020).

https://www.nature.com/articles/s41746-020-0239-1

- Wang, Y., Zhao, C., Wang, J. et al. Wearable plasmonic-metasurface sensor for noninvasive and universal molecular fingerprint detection on biointerfaces.

Science Advances 22 Jan 2021:

Vol. 7, no. 4, eabe4553

https://advances.sciencemag.org/content/7/4/eabe4553

- Gutruf, P., Krishnamurthi, V., Vázquez-Guardado, A. et al. Fully implantable optoelectronic systems for battery-free, multimodal operation in neuroscience research.

Nat Electron 1, 652–660 (2018).

http://rogersgroup.northwestern.edu/files/2018/nelectropto.pdf

- J. Choi, S. Chen, Y. Deng, Y. Xue, J.T. Reeder, D. Franklin, Y.S. Oh, J.B. Model, A.J. Aranyosi, S.P. Lee, R. Ghaffari, Y. Huang and J.A. Rogers,"Skin-Interfaced Microfluidic Systems that Combine Hard and Soft Materials for Demanding Applications in Sweat Capture and Analysis,"

Advanced Healthcare Materials 10, 2000722 (2021).

http://rogersgroup.northwestern.edu/files/2021/adhmskeleton.pdf