Information

Easy to use

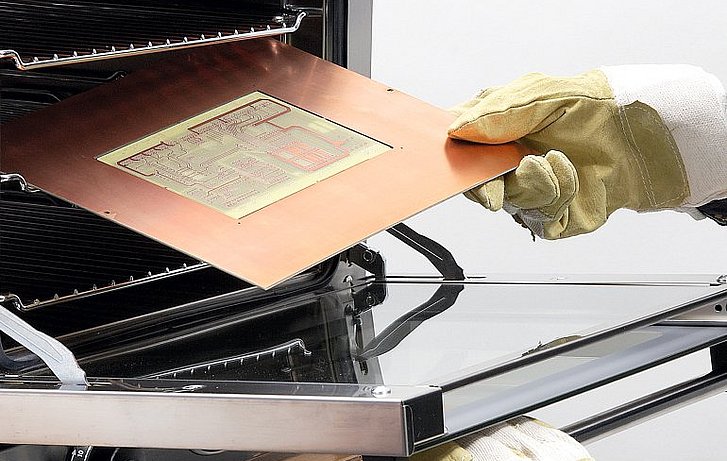

When combined with an LPKF circuit board plotter, complete PCB prototypes can be easily produced in one day. The production of PCB prototypes in your own laboratory enables you to achieve significantly shorter development cycles. Costs for external service providers are saved and valuable data remain safe in your own company.

Perfect result due to highly developed technology

The specially developed LPKF ProConduct through-hole plating process metallizes through-holes with a diameter of up to 0.4 mm and an aspect ratio of 1:4. Under special conditions, even holes with a smaller diameter can be through-plated. The electrical resistance of a fully plated through hole lies within a range of 10-25 m Ω. Even after 250 temperature change cycles, the resistance increases only slightly (max. 28 mΩ).