High Aspect Ratio Glass Microfluidics

Low-cost, deep micro-features open up the third dimension for everyone in micro-fluidics

Benefits of LIDE-processed glass for microfluidic application

With LIDE, microfeatures of single micron accuracy can be made in glass reliably and cost-effectively.

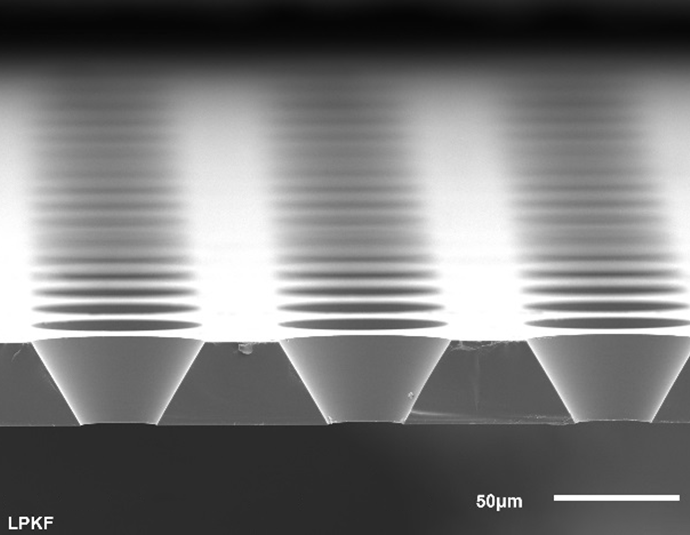

Aspect ratios of 1:10 can regularly be achieved and aspect ratios of up to 1:50 are possible when using the right glass. Contact us.

LIDE-processed glass keeps its initially smooth and optically transparent surface. The LIDE-processed glass channels have a roughness of Ra<0.8µm.

LIDE makes the cheap and easy generation of microfluidic feedthrough through glass possible, giving designers the opportunity to design complex microfluidics networks by making use of both sides of a glass substrate.

LIDE-processed glass can easily be functionalized by standard surface treatments.